Bridge Rectifiers

Bridge Rectifiers Specification

- Interface

- 2 Input, 2 Output Terminals

- Response Time

- Fast Switching

- Components

- 4 Diodes, Encapsulated Body

- Input

- AC Voltage Input

- Thermal Conductivity

- High

- Output

- DC Voltage Output

- Usage

- Rectification in Power Supplies

- Features

- High Surge Current Capability, Compact, Easy Installation

- Operating Temperature

- -40C to +125C

- Power Source

- Mains AC

- IP Rating

- IP20

- Power Supply

- AC

- Product Type

- Bridge Rectifier Module

- Application

- Industrial, Electronic Circuits, Power Management

- Rated Voltage

- 600V

- Supply Voltage

- 250V - 600V

- Size

- Standard Package

- Dimension (L*W*H)

- 28mm x 28mm x 7mm

- Function

- AC to DC Conversion

- Color

- Black

- Weight

- Approx. 10g

- Thickness

- Standard

- Current Rating

- 1A to 6A

- Capacity

- 1A/2A/4A/6A (varies by model)

- Frequency

- 50 Hz / 60 Hz

- Storage Temperature

- -55°C to +150°C

- Pin Type

- Leaded/Solderable Pins

- Polarity

- Clearly Marked

- Surge Current

- Up to 50A (variant specific)

- Mounting Type

- PCB Mount

- Compliance

- RoHS Compliant

- Isolation Voltage

- 1500V AC

- Reverse Voltage

- 600V max

- Package Type

- Square, Encapsulated

- Leakage Current

- < 5uA

- Case Material

- Molded Plastic

- Forward Voltage Drop

- 1.1V max per diode

About Bridge Rectifiers

Supplier & Trader of Bridge Rectifiers & SMD Inductor. Our product range also comprises of Electronic Components, SMD Eeletronics Components and Obsolete Electronic Components.Reliable Power Conversion

These bridge rectifiers are engineered to deliver consistent DC output from AC input, ensuring stability in industrial power management systems. The high surge current capability makes them well-suited for applications requiring robust performance and protection against voltage spikes. Their compact encapsulated body is designed for easy integration into standard PCB layouts, supporting a wide range of supply voltages.

Secure and Safe Installation

Featuring molded plastic housing and four leaded pins, these rectifiers are simple to mount on PCBs, greatly reducing installation time. The clearly marked polarity and encapsulated design enhance the safety and reliability of connections, minimizing risks of incorrect wiring or environmental exposure. With an IP20 rating, they offer dependable protection in varied operating environments.

Industrial Grade Performance

Built for demanding applications, these rectifiers operate reliably between -40C and +125C and withstand storage from -55C to +150C. The high isolation voltage and RoHS compliance ensure they meet stringent industry standards, offering peace of mind to distributors, importers, and suppliers across India. Their fast switching response and low forward voltage drop further optimize efficiency in electronic circuits.

FAQs of Bridge Rectifiers:

Q: How do I install a molded plastic bridge rectifier on a PCB?

A: Installation is straightforward: align the leaded, solderable pins with the PCB mounting holes, ensuring the clearly marked polarity matches the circuit requirements. Secure the device by soldering the pins, taking care to maintain proper insulation around the encapsulated body for optimal safety.Q: What is the maximum surge current and when is it relevant?

A: The bridge rectifiers can handle surge currents up to 50A, depending on the specific variant. This capacity is vital during power-on or transient events, protecting your electronics from damage caused by sudden current spikes.Q: Where are these bridge rectifiers typically used?

A: They are commonly integrated into industrial power supplies, electronic circuits, and power management systems requiring AC to DC conversion. Their compact size and high isolation voltage also make them suitable for modern automation and control applications.Q: What processes ensure the protection and reliability of this device?

A: Encapsulation in molded plastic provides robust insulation, while high thermal conductivity and isolation voltage up to 1500V AC help safeguard against overheating and electrical faults. RoHS compliance further ensures these rectifiers are safe for both users and the environment.Q: What are the benefits of using a bridge rectifier with fast switching and low forward voltage drop?

A: Fast switching enables prompt response to AC input changes, ensuring efficient DC output. The low forward voltage drop of 1.1V per diode minimizes energy loss and heat generation, improving overall system efficiency and longevity.Q: How does the leakage current affect the bridge rectifiers performance?

A: With leakage current rated at less than 5A, these rectifiers minimize undesirable current flow when reverse-biased, contributing to energy-efficient operation and protecting sensitive circuit components from potential damage.Q: What compliance and safety features do these rectifiers offer for industrial use in India?

A: They are RoHS compliant, feature an IP20 enclosure rating for safe handling, and provide a high isolation voltage. These characteristics ensure safe, reliable operation and adherence to regulatory standards for distributors, suppliers, and importers in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electronic Components Category

Dip Switches Relays

Color : Black with white actuator

Usage : Electronic control panels, circuit selection

Application : Industrial automation, electronic devices

Product Type : Dip Switches Relay

Size : Standard DIP footprint

Supply Voltage : 1224V DC

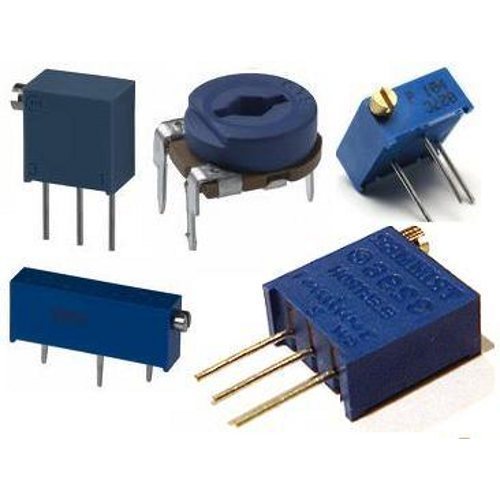

Trimpots

Color : Blue

Usage : Precision resistance tuning in PCBs, circuits, and modules

Application : Industrial control, consumer electronics, testing & calibration

Product Type : Trimmer Potentiometer (Trimpot)

Size : Standard: 3362P series, 9mm

Supply Voltage : Up to 50V DC

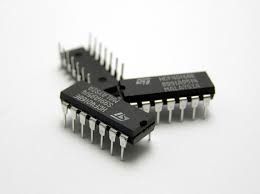

IC's

Color : Black

Usage : Electronic circuit integration

Application : Consumer electronics, Automotive, Industrial controls, Communication devices

Product Type : Integrated Circuit (IC)

Size : Standard package sizes (DIP, SMD, SIP, etc.)

Supply Voltage : Varies by IC; common: 3.3V, 5V, 12V

Dip Switches

Color : Red and White

Usage : Electronic devices, communication equipment

Application : PC boards, configuration settings, address selection

Product Type : DIP (Dual Inline Package) Switch

Size : Standard DIP

Supply Voltage : Up to 24V DC

GST : 07AKYPM5805H1ZN

|

COSMIC DEVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry