SMD Potentiometer

Price 14 INR/ Unit

SMD Potentiometer Specification

- Input

- Rotational or sliding adjustment

- Power Supply

- Direct electrical input

- Components

- Cermet, metal resistive track

- Features

- Compact size, SMD mounting, high reliability, RoHS compliant

- Resolution

- Fine adjustment, multi-turn type

- Power Source

- Circuit powered

- Operating Temperature

- -55C to +125C

- Interface

- SMD, 3-terminal

- Response Time

- Instantaneous mechanical adjustment

- Usage

- Used in electronic circuits for fine adjustment

- Output

- Variable resistance

- Product Type

- SMD Potentiometer

- Application

- Consumer electronics, industrial controls, medical devices, automotive systems

- Rated Voltage

- 50V DC

- Supply Voltage

- Up to 50V DC

- Size

- Trimmer 4mm (protected) package

- Dimension (L*W*H)

- 4.5 mm x 4.5 mm x 1.5 mm

- Function

- Variable resistor for adjusting and tuning electrical parameters

- Color

- Blue and white

- Weight

- Approximately 0.1g

- Current Rating

- Up to 100mA

- Thickness

- 1.5 mm

- Capacity

- Standard power rating 0.1W

About SMD Potentiometer

A potentiometer is also commonly known as apotmeterorpot. The most common form of potmeter is the single turn rotary potmeter. This type of pot is often used in audio volume control (logarithmic taper) as well as many other applications. Different materials are used to construct potentiometers, includingcarbon composition, cermet,wirewound, conductive plastic ormetal film.Reliable and Compact SMD Design

This potentiometer features a compact, space-saving SMD (Surface Mount Device) format, making it perfect for modern electronic assemblies where board real estate is at a premium. The robust UL 94V-0 flame-retardant case enhances safety, while the blue and white design aids visual identification during assembly and inspection.

Precision Adjustment and Versatile Application

With its top adjust and metal wiper, this trimmer potentiometer delivers precise, single-turn resistance control across a broad range (100 Ohm to 1 Mega Ohms). It excels in a variety of settings, from consumer electronics and industrial controllers to medical devices and automotive modules, accommodating any project needing fine tuning.

High Performance and Compliance

Engineered with a cermet and metal composite resistive track, the device ensures reliable operation for up to 200 cycles. It operates over a wide temperature range (-55C to +125C), withstands input voltages up to 50V DC, and holds RoHS compliance, guaranteeing environmental friendliness and endurance for professional and industrial use.

FAQs of SMD Potentiometer:

Q: How is this SMD potentiometer adjusted during circuit tuning?

A: This potentiometer is adjusted from the top using a small screwdriver or tool, allowing precise resistance changes in real time. Its single-turn mechanism enables swift and accurate fine-tuning of electrical parameters right on the assembly.Q: What are the main benefits of using this SMD potentiometer in electronic designs?

A: The primary benefits include its compact 4.5 mm package suitable for high-density layouts, reliable and repeatable adjustments, wide resistance range (100 Ohm1 Mega Ohms), and compliance with RoHS and UL 94V-0 safety standards, making it suitable for demanding environments.Q: When should I choose a potentiometer with a metal wiper and cermet track?

A: A potentiometer with a metal wiper and cermet resistive track should be chosen for applications requiring high reliability, minimal wear over time, and stable performance across broad temperatures, such as in industrial controllers, automotive electronics, or medical devices.Q: Where can this SMD potentiometer be installed?

A: This device is designed for surface mount technology (SMT) and can be installed on PCBs used in consumer electronics, industrial panels, medical device modules, automotive circuit boards, and a range of high-reliability systems.Q: What is the process for integrating this potentiometer into an SMD PCB layout?

A: Integration involves placing the potentiometer footprint in your PCB layout software, ensuring proper pads for the 3-terminal interface, and using standard SMT soldering techniques (reflow soldering) to mount the component during assembly.Q: How does the 20% tolerance affect its performance in critical applications?

A: While 20% tolerance allows for some variability in the exact resistance value, this level is common for trimmer potentiometers, which are primarily used for calibration and fine adjustment rather than absolute precision. For most tuning applications, this tolerance is typically acceptable.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electronic Components Category

Potentiometer

Color : Black with silver terminals

Frequency : DC or AC applications

Application : Laboratory, educational, instrumentation, audio equipment

Power Supply : Not Applicable (Passive Component)

Features : High accuracy, low noise, durable, easy installation

Usage : Electronic circuit calibration, volume/tone control, testing labs

Bridge Rectifiers

Color : Black

Frequency : 50 Hz / 60 Hz

Application : Industrial, Electronic Circuits, Power Management

Power Supply : AC

Features : High Surge Current Capability, Compact, Easy Installation

Usage : Rectification in Power Supplies

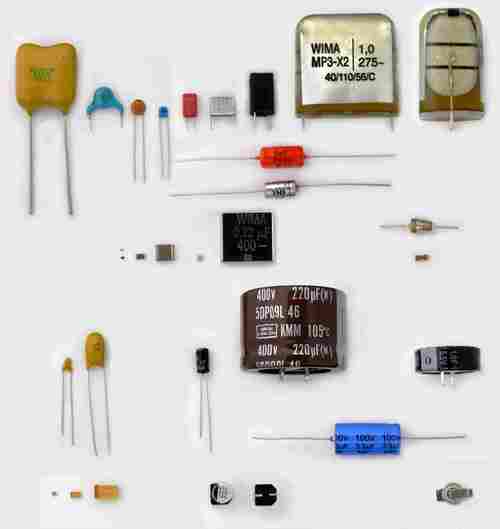

Capacitors

Color : Yellow, Blue, Black (varies by type)

Frequency : 50/60 Hz (for AC filtering)

Application : General Electronics, Power Supplies, Signal Processing

Power Supply : DC

Features : High stability, low leakage current, compact size

Usage : Electronic devices, power supplies, circuits

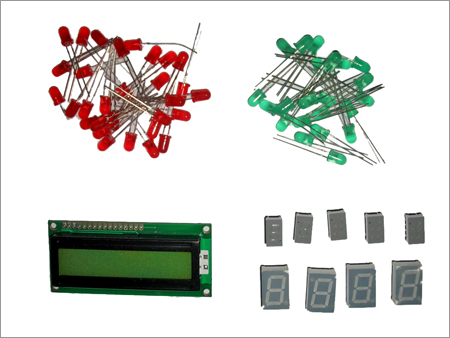

LED Display

Color : Different

Frequency : 50 Hertz (HZ)

Application : Industrial Use

Features : High Efficiency, Easy Installation, Excellent illumination

Usage : manufacturing of decorative lighting, electronic devices, signages, display boards and vehicles.

GST : 07AKYPM5805H1ZN

|

COSMIC DEVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry