Electronic Connectors

Electronic Connectors Specification

- Response Time

- Instantaneous connection/disconnection

- IP Rating

- IP20 IP67 (varies as per sealing and application)

- Usage

- Connectivity for PCBs, cable assemblies, power supplies, electronic devices, and components

- Operating Temperature

- -25C to +85C

- Features

- Compact design, secure locking, easy mounting, corrosion resistance

- Interface

- Male/Female, Board-to-Board, Wire-to-Board, Wire-to-Wire

- Components

- Housing, contact pins, locking mechanism

- Input

- Electrical signals

- Power Source

- External electrical supply

- Power Supply

- Electric

- Output

- Electrical signals

- Product Type

- Electronic Connector

- Application

- Industrial electronics, consumer electronics, communication devices, automotive, automation

- Rated Voltage

- 250V

- Supply Voltage

- Up to 250V AC/DC

- Size

- Miniature to Standard (varies as per connector type)

- Dimension (L*W*H)

- 10x5x5 mm to 60x20x20 mm (depends on type)

- Function

- Signal transmission and electrical connection for electronic circuits

- Color

- Multicolor (varies by connector type)

- Weight

- Approx. 5g 50g (depending on type and size)

- Thickness

- 2 mm 6 mm (varies by model)

- Capacity

- Multiple pin configurations (2 pin, 3 pin, 4 pin, etc.)

- Current Rating

- Up to 5A (varies by type)

- Frequency

- DC to 500 MHz (application dependent)

- Flame Retardant

- UL94V-0 housing materials

- Contact Plating

- Gold/Tin over Nickel

- Material

- High-grade plastic and copper alloy contacts with tin/gold plating

- Cable Compatibility

- Flat cable, ribbon cable, discrete wire, coaxial cables

- Mounting Type

- Through-hole, Surface Mount (SMD/SMT), Panel Mount

- Number of Contacts

- 2 to 40+ (varies by model)

- Mechanical Durability

- 500 mating cycles

- Insulation Resistance

- >1000 M at 500V DC

- Contact Resistance

- 20 m

- Connector Types

- Header, Socket, Terminal block, Circular, D-sub, FFC/FPC, RJ45, USB, etc.

- Standards Compliance

- RoHS, REACH, UL certified depending on type

About Electronic Connectors

Cosmic Devices is the noted as Trader, Supplier and Importerof Industrial Electronic Components, All Type of SMD Electronic Components, Reed Switches, Buzzers, Crystals, Diodes, Integrated Circuits, LED & Displays, Transistors. We strive to achieve a leading position within our markets, satisfying the customers with the introduction of products that purely complement our existing range. Our USP is defined by customer satisfaction and expansion of the client base. We can arrange all Odd Components as per your requirements with minimum lead time.Reliable Connections for Diverse Applications

Our connectors offer secure and efficient electrical connections for PCBs, cable assemblies, and electronic devices. Featuring UL94V-0 flame-retardant housings, multiple pin configurations, and IP ratings up to IP67, these connectors are ideal for industrial control, automotive systems, communication infrastructure, and consumer electronics. Their compact design and easy mounting cater to both high-density and standard requirements.

Advanced Materials and Compliance

Each connector employs premium-grade plastic for insulation and copper alloy contacts, with gold or tin plating for superior signal integrity. Compliance with RoHS, REACH, and (depending on type) UL certification ensures safety and environmental responsibility, supporting both domestic and international standards.

FAQs of Electronic Connectors:

Q: How do I select the appropriate connector type for my application?

A: The connector type depends on factors like signal or power transmission needs, pin count, mounting method (through-hole, SMD/SMT, panel), and cable compatibility. Assess your PCB layout, operating environment, and mechanical durability requirements to choose between headers, sockets, D-sub, FFC/FPC, RJ45, USB, or circular connectors.Q: What are the benefits of copper alloy contacts with gold/tin plating?

A: Copper alloy contacts provide excellent conductivity and mechanical strength, while gold or tin plating over nickel ensures superior corrosion resistance, lower contact resistance (20 m), and enhanced reliability even after repeated mating cycles.Q: What is the typical usage process for mounting these connectors?

A: Depending on the mounting type, connectors can be soldered onto PCBs (through-hole, SMD/SMT) or attached using panel mounts. Carefully align connectors to the designated footprint or panel aperture, secure as specified, and ensure proper mating of male/female interfaces during assembly.Q: Where can these connectors be used?

A: They are suitable for connectivity in industrial electronics, automation systems, automotive electronics, communication devices, and consumer gadgets. Their wide rating range, pin configurations, and cable compatibilities support various devices and assemblies across these sectors.Q: When should I consider IP-rated connectors for my project?

A: Use IP-rated connectors (IP20 to IP67) when your application requires protection against dust, moisture, or immersion. Higher IP ratings are recommended for outdoor, automotive, or industrial environments where robust sealing is vital for performance and safety.Q: What makes these connectors flame-retardant and safe for high-power usage?

A: Connectors feature UL94V-0 flame-retardant housing materials and are rated up to 250V/5A, ensuring safety in high-voltage or high-current applications. Their compliance with UL, RoHS, and REACH standards adds further assurance for demanding operational environments.Q: What is the mechanical durability of these connectors and how does it benefit my design?

A: With a guaranteed endurance of 500 mating cycles, these connectors provide lasting reliability, minimizing maintenance costs and downtime, making them ideal for devices subject to frequent connections and disconnections.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electronic Components Category

Industrial MOSFET

Color : Black, Silver

Product Type : Industrial MOSFET

Usage : Industrial electronic circuits and power control

Features : Low onresistance, high efficiency, reliable performance

Application : Motor drivers, power supplies, inverters, switching regulators

NTC

Color : Black

Product Type : NTC Thermistor

Usage : Overheat Protection

Features : High Accuracy, Fast Response, Compact Size

Application : Electronics, Household Appliances, Power Supply Units

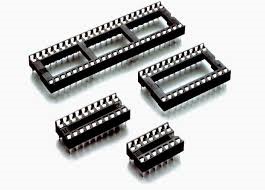

IC Sockets

Color : Black

Product Type : IC Socket

Usage : Used for mounting ICs onto PCBs

Features : Easy IC replacement, corrosionresistant contacts, reliable connection, durable construction

Application : Electronics projects, circuit prototyping, repair, and testing

Ceramic Capacitors

Minimum Order Quantity : 10 Pieces

Color : as shown in the image

Product Type : ceramic capacitors

Usage : Industrial

Features : High Quality

Application : Electrical & Electronics

GST : 07AKYPM5805H1ZN

|

COSMIC DEVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry