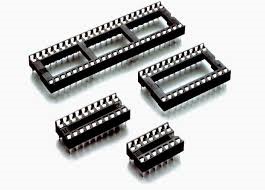

IC Sockets

IC Sockets Specification

- IP Rating

- Not rated

- Interface

- DIP through-hole

- Usage

- Used for mounting ICs onto PCBs

- Operating Temperature

- -40C to +105C

- Features

- Easy IC replacement, corrosion-resistant contacts, reliable connection, durable construction

- Components

- Plastic body, Phosphor bronze or brass contacts

- Product Type

- IC Socket

- Application

- Electronics projects, circuit prototyping, repair, and testing

- Rated Voltage

- 250V AC

- Supply Voltage

- Up to 250V AC

- Size

- Standard DIP (Dual In-line Package); available in various pin counts

- Dimension (L*W*H)

- Varies as per pin number, e.g., 25.5mm x 7mm x 2mm for 16-pin model

- Function

- Provides a replaceable interface between integrated circuits and PCB for easy installation or replacement

- Color

- Black

- Weight

- Approximately 2g per socket

- Thickness

- 2 mm approx

- Current Rating

- 1A max per contact

- Capacity

- Supports standard DIP IC packages

About IC Sockets

We are offering a wide range ofIC Sockets which are procured from the reliable vendors. Our IC Sockets are made from quality material. The whole product range is stringently tested by our expert quality controllers. These are in-built with molded plastic enclosure and all in one logical in one monitor design.

Features:

1. Beginners

2. Self-learners

3. Class room teaching

4. Training and development purposes

Reliable Connection for Your PCBs

Engineered for easy IC replacement and dependable connectivity, these DIP IC sockets offer corrosion-resistant, tin or gold-plated contacts over nickel. Their precision construction ensures low contact resistance and secure connections in all standard DIP configurations, supporting a variety of electronics and circuit prototyping tasks.

Versatile Pin Counts and Sizes

Whether your project uses 8, 14, 16, up to 40 pins or more, these IC sockets accommodate a wide array of integrated circuit packages. The dimensions adapt according to pin number, ensuring compatibility with most PCB layouts and electronics requirements.

Durable and Safe Design

Manufactured using robust PBT or top-grade plastics and compliant with RoHS directives, these sockets withstand harsh environments with storage temperatures from -55C to +125C and operational ranges from -40C to +105C. High insulation ratings and dielectric strength ensure safe and long-lasting use.

FAQs of IC Sockets:

Q: How do IC sockets facilitate easy installation and replacement of integrated circuits on PCBs?

A: IC sockets provide a replaceable interface between integrated circuits and PCBs, allowing users to insert or remove chips without soldering. This simplifies the installation or replacement process during prototyping, maintenance, or repair, reducing the risk of damage to delicate IC leads.Q: What pin counts and mounting types are available for these IC sockets?

A: These IC sockets are available in standard DIP configurations with pin counts of 8, 14, 16, 18, 20, 24, 28, 40, and more. They feature a through-hole mounting type, making them compatible with most PCB designs used in electronics projects.Q: When should I choose IC sockets with gold-plated contacts over tin-plated ones?

A: Gold-plated contacts are recommended for environments that require enhanced corrosion resistance, frequent insertion cycles, or higher conductivity. Tin-plated contacts offer reliable performance for typical applications where cost considerations are prioritized and environmental demands are moderate.Q: Where can these IC sockets be used in electronics projects or repair work?

A: These sockets are suitable for use in a variety of applications, including circuit prototyping, electronics projects, IC testing, and repair work. Their design supports standard DIP IC packages, making them ideal for both professional and hobbyist settings.Q: What process should I follow when mounting these IC sockets to a PCB?

A: To mount the sockets, align the pins with the PCB holes and insert the socket so that it sits flush on the board. Solder each pin to the corresponding PCB pad, ensuring a solid mechanical and electrical connection. Avoid overheating to preserve the integrity of the plastic body and plated contacts.Q: How does the UL 94V-0 flammability rating benefit my electronics project?

A: The UL 94V-0 rating indicates that the sockets housing material is flame-retardant, providing enhanced safety in case of electrical faults or overheating. This ensures compliance with safety standards and protects PCBs in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electronic Components Category

Integrated Circuit

Color : Black

Frequency : Up to 40 MHz

Product Type : Integrated Circuit (IC)

Dimension (L*W*H) : 12 mm x 7 mm x 1.2 mm

Features : Low Power Consumption, Reliable, Miniature Size

Supply Voltage : 3.3V to 5V

Tantalum Capacitors

Color : Yellow/Gold

Frequency : Up to 100kHz application frequency

Product Type : Tantalum Capacitor

Dimension (L*W*H) : e.g., 3.2mm x 1.6mm x 1.6mm (varies)

Features : Polarized, low ESR, compact, stable capacitance

Supply Voltage : 6.3V to 35V

Dip Switches Relays

Color : Black with white actuator

Frequency : DC and lowfrequency switching

Product Type : Dip Switches Relay

Dimension (L*W*H) : 25mm x 10mm x 6mm

Features : Compact, easy installation, reliable switching

Supply Voltage : 1224V DC

Electronic Connectors

Color : Multicolor (varies by connector type)

Frequency : DC to 500 MHz (application dependent)

Product Type : Electronic Connector

Dimension (L*W*H) : 10x5x5 mm to 60x20x20 mm (depends on type)

Features : Compact design, secure locking, easy mounting, corrosion resistance

Supply Voltage : Up to 250V AC/DC

GST : 07AKYPM5805H1ZN

|

COSMIC DEVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry